Nissan Maxima Service and Repair Manual: P0420, P0430 three way catalyst function

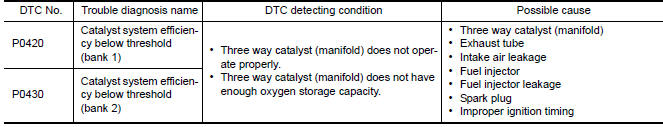

DTC Logic

DTC DETECTION LOGIC

The ECM monitors the switching frequency ratio of air fuel ratio (A/F) sensor 1 and heated oxygen sensor 2.

A three way catalyst (manifold) with high oxygen storage capacity will indicate a low switching frequency of heated oxygen sensor 2.

As oxygen storage capacity decreases, the heated oxygen sensor 2 switching frequency will increase.

When the frequency ratio of A/F sensor 1 and heated oxygen sensor 2 approaches a specified limit value, the three way catalyst (manifold) malfunction is diagnosed.

DTC CONFIRMATION PROCEDURE

1.INSPECTION START

2.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION: Do not maintain engine speed for more than the specified minutes below.

3.PERFORM DTC CONFIRMATION PROCEDURE-I

With CONSULT

- Turn ignition switch ON and select "DATA MONITOR" mode with CONSULT.

- Start engine and warm it up to the normal operating temperature.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

- Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

- Let engine idle for 1 minute.

- Check that "COOLAN TEMP/S" indicates more than 70C (158F).

If not, warm up engine and go to next step when "COOLAN TEMP/S" indication reaches to 70C (158F).

- Open engine hood.

- Select "DTC & SRT CONFIRMATION" then "SRT WORK SUPPORT" mode with CONSULT.

- Rev engine between 2,000 and 3,000 rpm and hold it for 3 consecutive minutes then release the accelerator pedal completely.

- Check the indication of "CATALYST".

4.PERFORM DTC CONFIRMATION PROCEDURE-II

- Wait 5 seconds at idle.

- Rev engine between 2,000 and 3,000 rpm and maintain it until "INCMP" of "CATALYST" changes to "CMPLT" (It will take approximately 5 minutes).

5.PERFORM DTC CONFIRMATION PROCEDURE AGAIN

- Stop engine and cool it down to less than 70C (158F).

- Perform DTC CONFIRMATION PROCEDURE again.

6.PERFORM DTC CONFIRMATION PROCEDURE-III

Check 1st trip DTC

7.PERFORM COMPONENT FUNCTION CHECK

Perform component function check

NOTE: Use component function check to check the overall function of the three way catalyst (manifold). During this check, a 1st trip DTC might not be confirmed.

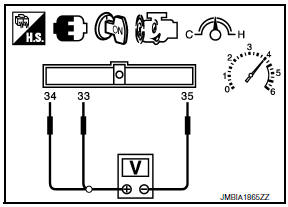

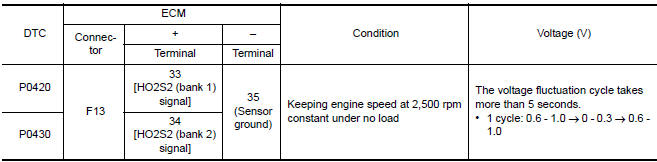

Component Function Check

1.PERFORM COMPONENT FUNCTION CHECK

Without CONSULT

- Start engine and warm it up to the normal operating temperature.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

- Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

- Let engine idle for 1 minute.

- Open engine hood.

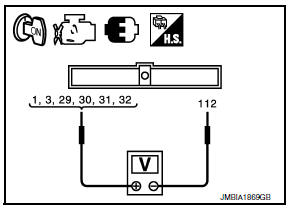

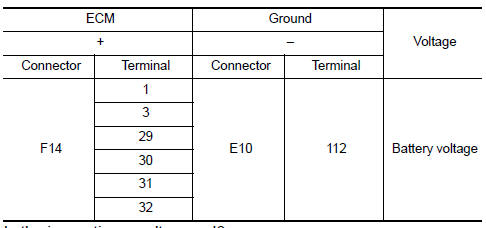

- Check the voltage between ECM harness connector terminals under the following conditions.

Diagnosis Procedure

1.CHECK EXHAUST SYSTEM

Visually check exhaust tubes and muffler for dents.

2.CHECK EXHAUST GAS LEAKAGE

- Start engine and run it at idle.

- Listen for an exhaust gas leakage before the three way catalyst (manifold).

3.CHECK INTAKE AIR LEAKAGE

Listen for an intake air leakage after the mass air flow sensor.

4.CHECK IGNITION TIMING

Check idle speed and ignition timing.

5.CHECK FUEL INJECTORS

- Stop engine and then turn ignition switch ON.

- Check the voltage between ECM harness connectors.

6.CHECK FUNCTION OF IGNITION COIL-I

CAUTION: Perform the following procedure in a place with no combustible objects and good ventilation.

- Turn ignition switch OFF.

- Remove fuel pump fuse in IPDM E/R to release fuel pressure.

NOTE: Do not use CONSULT to release fuel pressure, or fuel pressure applies again during the following procedure.

- Start engine.

- After engine stalls, crank it two or three times to release all fuel pressure.

- Turn ignition switch OFF.

- Remove all ignition coil harness connectors to avoid the electrical discharge from the ignition coils. Refer to EM-42, "Removal and Installation (LH)" or EM-42, "Removal and Installatio (RH)".

- Remove ignition coil and spark plug of the cylinder to be checked.

- Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

- Connect spark plug and harness connector to ignition coil.

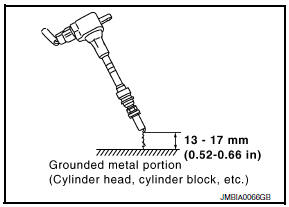

- . Fix ignition coil using a rope etc. with gap of 13 - 17 mm (0.52 - 0.66 in) between the edge of the spark plug and grounded metal portion as shown in the figure.

- Crank engine for about 3 seconds, and check whether spark is generated between the spark plug and the grounded metal portion.

Spark should be generated

CAUTION:

- Never place the spark plug and the ignition coil within 50 cm (19.7 in) each other. Be careful not to get an electrical shock while checking, because the electrical discharge voltage becomes 20 kV or more.

- It might damage the ignition coil if the gap of more than 17 mm (0.66 in) is made.

NOTE: When the gap is less than 13 mm (0.52 in), a spark might be generated even if the coil is malfunctioning.

7.CHECK FUNCTION OF IGNITION COIL-II

- Turn ignition switch OFF.

- Disconnect spark plug and connect a non-malfunctioning spark plug.

- Crank engine for about 3 seconds, and recheck whether spark is generated between the spark plug and the grounded metal portion.

Spark should be generated

8.CHECK SPARK PLUG

Check the initial spark plug for fouling, etc.

9.CHECK FUNCTION OF IGNITION COIL-III

- Reconnect the initial spark plugs.

- Crank engine for about three seconds, and recheck whether spark is generated between the spark plug and the grounded portion.

10.CHECK FUEL INJECTOR

- Turn ignition switch OFF.

- Remove fuel injector assembly.

Refer to EM-43, "Removal and Installation".

Keep fuel hose and all fuel injectors connected to fuel tube.

- Disconnect all ignition coil harness connectors.

- Reconnect all fuel injector harness connectors disconnected.

- Turn ignition switch ON.

Check that fuel does not drip from fuel injector.

11.CHECK INTERMITTENT INCIDENT

P0340, P0345 CMP sensor (PHASE)

P0340, P0345 CMP sensor (PHASE)

Description

The camshaft position sensor (PHASE) senses the retraction of

camshaft (INT) to identify a particular cylinder. The camshaft position

sensor (PHASE) senses the piston position.

...

P0441 evap control system

P0441 evap control system

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0441 is displayed with other DTC such as P2122, P2123, P2127, P2128 or

P2138, first perform

trouble diagnosis for other DTC.

In this evaporative em ...

Other materials:

P0740 torque converter

Description

The torque converter clutch solenoid valve is activated by the TCM

in response to signals sent from the vehicle

speed and accelerator pedal position sensors. Lock-up piston operation will

then be controlled.

Lock-up operation, however, is prohibited when CVT fl ...

Tire Pressure Monitoring System (TPMS)

Each tire, including the spare (if provided),

should be checked monthly when cold and inflated

to the inflation pressure recommended by

the vehicle manufacturer on the vehicle placard

or tire inflation pressure label. (If your vehicle has

tires of a different size than the size indicated on

th ...

Ground

Ground Distribution

MAIN HARNESS

ENGINE ROOM HARNESS

FRONT END MODULE HARNESS

ENGINE CONTROL HARNESS

BODY HARNESS

BODY NO. 2 HARNESS

...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0059