Nissan Maxima Service and Repair Manual: P0443 evap canister purge volume control solenoid valve

Description

The EVAP canister purge volume control solenoid valve is used to control the flow rate of fuel vapor from the EVAP canister. The EVAP canister purge volume control solenoid valve is moved by ON/OFF pulses from the ECM. The longer the ON pulse, the greater the amount of fuel vapor that will flow via the valve.

DTC Logic

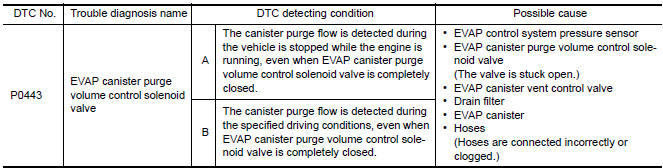

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

TESTING CONDITION:

- Perform DTC CONFIRMATION PROCEDURE when the fuel is between 1/4 and 3/4 full, and vehicle is placed on flat level surface.

- Always perform test at a temperature of 5 to 60C (41 to 140F).

- Cool the vehicle so that engine coolant temperature becomes same level as ambient temperature.

2.PERFORM DTC CONFIRMATION PROCEDURE A

With CONSULT

- Turn ignition switch ON.

- Select "DATA MONITOR" mode with CONSULT.

- Check that the following condition are met.

FUEL T/TMP SE: 0 - 35C (32 - 95F)

- Start engine and wait at least 60 seconds.

- Check 1st trip DTC.

3.PERFORM DTC CONFIRMATION PROCEDURE B

With CONSULT

- Start engine and warm it up to normal operating temperature.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Select "PURG VOL CN/V P1444" of "EVAPORATIVE SYSTEM" in "DTC WORK SUPPORT" mode with CONSULT.

- Touch "START".

- Start engine and let it idle until "TESTING" on CONSULT changes to "COMPLETED". (It will take approximately 10 seconds.) If "TESTING" is not displayed after 5 minutes, retry from step 2.

- Touch "SELF-DIAG RESULT".

4.PERFORM DTC CONFIRMATION PROCEDURE A

With GST

- Turn ignition switch ON.

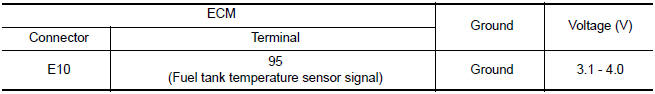

- Check the voltage between ECM harness connector and ground.

- Start engine and wait at least 60 seconds.

- Check 1st trip DTC.

5.PERFORM DTC CONFIRMATION PROCEDURE

With GST

- Start engine and warm it up to normal operating temperature.

- Turn ignition switch OFF and wait at least 10 seconds.

- Start engine and let it idle for at least 20 seconds.

- Check 1st trip DTC.

Diagnosis Procedure

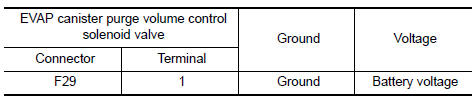

1.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect EVAP canister purge volume control solenoid valve harness connector.

- Turn ignition switch ON.

- Check the voltage between EVAP canister purge volume control solenoid valve harness connector and ground.

2.DETECT MALFUNCTIONING PART

Check the following.

- Harness connectors E11, F2

- Junction block connectors E44, E45

- Harness for open or short between EVAP canister purge volume control solenoid valve and IPDM E/R

- Harness for open or short between EVAP canister purge volume control solenoid valve and ECM

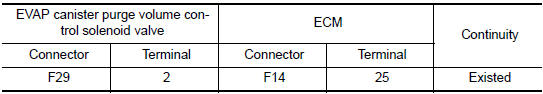

3.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between EVAP canister purge volume control solenoid valve harness connector and ECM harness connector.

- Also check harness for short to ground and short to power

4.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR CONNECTOR

- Disconnect EVAP control system pressure sensor harness connector.

- Check that water is not inside connectors.

5.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

6.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

With CONSULT

- Turn ignition switch OFF.

- Reconnect harness connectors disconnected.

- Start engine.

- Perform "PURG VOL CONT/V" in "ACTIVE TEST" mode with CONSULT. Check that engine speed varies according to the valve opening.

7.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

8.CHECK RUBBER TUBE FOR CLOGGING

- Disconnect rubber tube connected to EVAP canister vent control valve.

- Check the rubber tube for clogging.

9.CHECK DRAIN FILTER

10.CHECK EVAP CANISTER VENT CONTROL VALVE

11.CHECK IF EVAP CANISTER IS SATURATED WITH WATER

Remove EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor attached.

12.CHECK EVAP CANISTER

Weigh the EVAP canister with the EVAP canister vent control valve and EVAP control system pressure sensor attached.

The weight should be less than 2.1 kg (4.6 lb).

13.DETECT MALFUNCTIONING PART

Check the following.

- EVAP canister for damage

- EVAP hose between EVAP canister and drain filter for clogging or poor connection

14.CHECK INTERMITTENT INCIDENT

Component Inspection

EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

1.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

With CONSULT

- Turn ignition switch OFF.

- Reconnect all harness connectors disconnected.

- Disconnect EVAP purge hoses connected to EVAP canister purge volume control solenoid valve.

- Turn ignition switch ON.

- Select "PURG VOL CONT/V" in "ACTIVE TEST" mode with CONSULT.

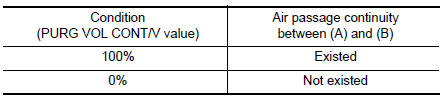

- Touch "Qd" and "Qu" on CONSULT screen to adjust "PURG VOL CONT/V" opening and check air passage continuity of EVAP canister purge volume control solenoid valve under the following conditions.

Without CONSULT

- Turn ignition switch OFF.

- Disconnect EVAP canister purge volume control solenoid valve harness connector.

- Disconnect EVAP purge hoses connected to EVAP canister purge volume control solenoid valve.

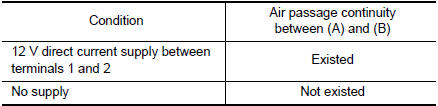

- Check air passage continuity of EVAP canister purge volume control solenoid valve under the following conditions.

DRAIN FILTER

- Check visually for insect nests in the drain filter air inlet.

- Check visually for cracks or flaws in the appearance.

- Check visually for cracks or flaws in the hose.

- Blow air into port A and check that it flows freely out of port B.

- Block port B.

- Blow air into port A and check that there is no leakage.

- If NG, replace drain filter.

P0442 evap control system

P0442 evap control system

DTC Logic

DTC DETECTION LOGIC

This diagnosis detects leakage in the EVAP purge line using engine intake

manifold vacuum.

If pressure does not increase, the ECM will check for leakage in the lin ...

P0444, P0445 evap canister purge volume control solenoid

valve

P0444, P0445 evap canister purge volume control solenoid

valve

Description

The EVAP canister purge volume control solenoid valve is used to

control the flow rate of fuel vapor from the EVAP canister. The EVAP

canister purge volume control solenoid valve ...

Other materials:

U1000 can comm circuit

Description

CAN (Controller Area Network) is a serial communication line for real time

applications. It is an on-vehicle multiplex

communication line with high data communication speed and excellent error

detection ability. Modern

vehicles are equipped with many electronic control units, an ...

Normal operating condition

Description

The majority of the audio concerns are the result of outside causes (bad CD,

electromagnetic interference,

etc.).

NOISE

The following noise results from variations in field strength, such as fading

noise and multi-path noise, or

external noise from trains and other sources. I ...

Wiring diagram

MONOCHROME DISPLAY

Wiring Diagram - With BOSE Audio System

...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0066