Nissan Maxima Service and Repair Manual: Steering column

Without Electric Motor

- -4. Steering column assembly nut tightening order

- Steering wheel

- Combination switch and spiral cable

- Steering column assembly

- Hole cover seal

- Herbie clip

- Hole cover

- Lower shaft assembly

With Electric Motor

- -4. Steering column assembly nut tightening order

- Steering wheel

- Combination switch and spiral cable

- Steering column assembly

- Hole cover seal

- Herbie clip

- Hole cover

- Lower shaft assembly

Removal and Installation

REMOVAL

Hole Cover Seal, Hole Cover and Lower Shaft Assembly

- Set wheels to the straight-ahead position.

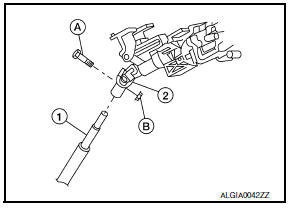

- Remove lower side bolt (A) of lower shaft assembly (1).

- Steering gear (2)

- Remove the instrument lower panel LH.

- Remove bolt (A) and nut (B) of column upper joint (2), then remove lower shaft assembly (1). CAUTION: Do not reuse column upper joint nut.

- Loosen herbie clip, then remove hole cover seal from hole cover.

- Remove nuts of hole cover, and then remove clamp and hole cover from dash panel.

Steering Column Assembly

- Set wheels to the straight-ahead position.

- Remove instrument side finisher (LH). Refer to IP-10, "Exploded View".

- Remove instrument lower panel LH. Refer to IP-19, "Removal and Installation".

- Remove lower knee protector (LH) bolts (

)(, then remove lower knee protector (LH)

(1). Refer to IP-10, "Exploded View".

)(, then remove lower knee protector (LH)

(1). Refer to IP-10, "Exploded View". - Remove steering column upper and lower covers. Refer to IP- 10, "Exploded View".

- Remove combination switch and spiral cable. Refer to SR-15, "Removal and Installation".

- Disconnect each switch harness connector installed to steering column assembly, and then disconnect harness clips from steering column assembly.

- Remove bolt (A) and nut (B) of column upper joint (2).

- Lower shaft assembly (1)

CAUTION: Do not reuse column upper joint nut.

- Remove steering column assembly nuts, then remove steering column assembly.

INSPECTION AFTER REMOVAL

Hole Cover Seal, Hole Cover and Lower Shaft Assembly Check each part of hole cover seal, hole cover and steering column and lower shaft assembly for damage or other malfunctions. Replace if necessary.

Steering Column Assembly

- Check each part of steering column assembly for damage or other malfunctions. Replace entire steering column assembly if any parts are damaged.

- Measure the length (L) as shown if vehicle has been involved in a minor collision. Replace steering column assembly if outside the specifications.

- Measure steering column rotating torque using Tool. Replace steering column assembly if outside the standard.

Tool number : ST3127S000 (J-25765-A)

- Check tilt and telescopic mechanism operating range (L1), (L2) as shown.

INSTALLATION

Hole Cover Seal, Hole Cover and Lower Shaft Assembly

Installation is in the reverse order of removal.

- When installing lower shaft assembly to steering gear assembly, follow the procedure listed below.

- Set rack of steering gear in the neutral position. NOTE: To get the neutral position of rack, turn gear sub-assembly and measure the distance of inner socket, and then measure the intermediate position of the distance.

- Align rear cover cap projection (A) with the marking position (B) of gear housing assembly.

- Install slit part of lower shaft assembly (C) aligning with the projection (A) of rear cover cap (1). Make sure that the slit part of lower shaft assembly (C) is aligned with both the projection (A) of rear cover cap (1) and the marking position (B) of gear housing assembly.

Steering Column Assembly

Installation is in the reverse order of removal.

Telescopic motor

Telescopic motor

Exploded View

Steering column assembly

Telescope motor

Telescope motor link bracket

Tilt motor

Tilt motor bolt cap

Removal and Installation

REMOVAL

Remove instrument lower pan ...

Steering gear and linkage

Steering gear and linkage

Exploded View

Cotter pin

Steering gear assembly Front

Removal and Installation

NOTE: When removing components such as

hoses, tubes/lines, etc., cap or plug openings to prevent fluid ...

Other materials:

Extended storage switch

The extended storage switch is used when the

vehicle is in transit from the factory. It is located in

the fuse panel to the left of the steering wheel on

the instrument panel. If any electrical equipment

does not operate, ensure the extended storage

switch is pushed fully in place, as shown ...

Rear stabilizer

Removal and Installation

Removal

Remove each rear stabilizer connecting rod nut using power tools.

Disconnect the rear stabilizer from each rear stabilizer

connecting rod.

Remove each rear stabilizer clamp bolt using power tools.

Remove the rear stabilizer.

If necessary, remove each ...

Additional service when replacing transaxle assembly

Description

When replacing the transaxle assembly, perform the following work.

ERASING, LOADING AND STORING OF CALIBRATION DATA

The TCM acquires calibration data (individual characteristic

value) of each solenoid that is stored in the

ROM assembly (in the control valve). This enabl ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0069